Nahttypen (seam types) are more than a sewing detail. In modern products, the seam can decide whether something feels premium, survives daily stress, or fails early. From clothing and upholstery to medical textiles and industrial covers, the “right seam” is basically a small engineering choice hidden in plain sight.

When you zoom out, seams act like load paths. They move tension across materials, protect edges from fraying, and shape how a product flexes. That is why Nahttypen matter in technology-driven manufacturing, where speed, repeatability, and quality targets are strict, and even tiny weaknesses can become big warranty problems.

This guide breaks Nahttypen down in a practical way. You will learn how seams fail, which seam types boost strength, how industrial joining fits into the idea of “seams,” and what makes a seam “smart.” By the end, you should be able to choose seam types faster, with fewer surprises in testing.

Understanding Nahttypen in modern production

Nahttypen literally means “types of seams,” but in production it also includes how two materials are joined and finished. A seam is not only a line of thread. It is a designed connection that considers material behavior, stress direction, and how the edge is treated. In tech manufacturing, Nahttypen decisions also affect cycle time, automation options, and how consistently the seam can be inspected.

Stitch, seam, and joint: clearing up the terms

A stitch is the actual thread interlacing pattern. A seam is the full construction, including layers, allowances, and finishing. A joint is the broad idea of connecting parts, which can include stitches, welds, adhesives, or ultrasonic bonding. When people say “Nahttypen,” they often mix all three. Getting clear on this vocabulary helps teams communicate better during design reviews and production setup.

Why seam type is a technology decision

Seam choices decide more than appearance. They control strength, stretch, leak resistance, and how the product behaves after washing, heat, or chemicals. They also determine which machines can build the product and how many steps are needed. A seam that looks simple may require strict alignment or special thread. In factories, Nahttypen are often chosen for reliability first, then cost, then styling.

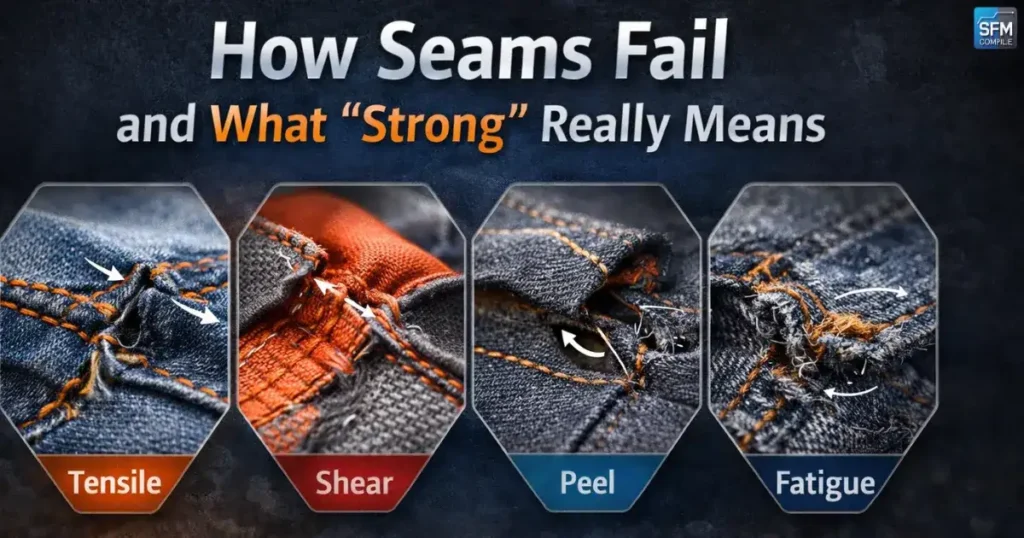

How seams fail and what “strong” really means

A “strong seam” is not one thing. Some products need high tensile strength, others need resistance to tearing, peeling, abrasion, or repeated bending. Failure can happen in thread, fabric, or at the edge where holes weaken the material. Nahttypen work best when they match the exact kind of force the seam will see in real life, not just in a single test.

Tensile, shear, peel, and fatigue forces

Tensile force pulls straight apart, shear slides layers, and peel forces lift one edge like opening tape. Fatigue is repeated loading that slowly damages thread and fibers. Many seam failures are fatigue-related, especially in sportswear, bags, and upholstery. A seam that holds a big static load can still fail fast when it is flexed thousands of times in use, washing, or temperature changes.

Stress concentration and edge effects

Seams can create stress concentrations because needle holes weaken the material and concentrate force along a line. Edges can also fray, split, or curl, which changes how load travels. Some Nahttypen spread stress across a wider area, while others focus it tightly. Designs that include topstitching, folding, or lapped layers often last longer because they distribute force and protect raw edges from damage.

Textile Nahttypen that boost durability

In stitched textiles, durability comes from three things: layer management, edge finishing, and how the seam line spreads load. Some seam types hide raw edges to reduce fraying. Others lock multiple layers to increase tear resistance. The best Nahttypen for strength often look slightly “overbuilt,” but they pay off when products face abrasion, washing, and heavy use over time.

Plain seam, French seam, and flat-felled seam

A plain seam is common and fast, but it can leave edges vulnerable unless finished. A French seam encloses raw edges inside, improving durability and comfort, especially in lightweight fabrics. A flat-felled seam folds and stitches layers down for a strong, clean finish seen in jeans and workwear. Flat-felled seams resist fraying and handle repeated stress well, but they take more steps.

Overlock and coverstitch seams in performance wear

Overlock seams (serged seams) cut, finish, and stitch edges in one process, which is great for speed and fray control. They are common in knitwear and activewear, especially when stretch matters. Coverstitch seams add a flexible, durable finish on hems and seams, keeping fabric flat while allowing movement. These Nahttypen are popular because they balance comfort, stretch, and production efficiency.

Industrial Nahttypen beyond traditional sewing

In many technical products, “seams” are not made with thread at all. Think of welded tarps, heat-sealed medical items, or bonded composites. These are still Nahttypen because they create joining lines with specific strength and sealing behavior. Industrial seam types can reduce puncture holes, improve waterproofing, and support automation, but they also require tight process control and compatible materials.

Weld seams: butt, lap, and fillet style joining

Welded seam concepts show up in metals, plastics, and technical fabrics. A butt-style join brings edges together, while a lap join overlaps layers for more area and strength. Fillet-like weld geometry can reinforce corners and transitions where stress concentrates. In textile-like materials, heat welding or RF welding creates a fused seam line that can be stronger than stitching and can be watertight.

Adhesive bonds and ultrasonic seams

Adhesive bonding spreads load across a large surface, which helps with peel and fatigue if designed correctly. It can also keep surfaces smooth and reduce irritation in wearable products. Ultrasonic seams use vibration and pressure to fuse synthetic materials, often producing clean, repeatable seams fast. These Nahttypen depend heavily on material compatibility, surface prep, and consistent machine settings to avoid weak spots.

Also Read This Blog: “Mylawyer360.com Criminal: The Smart Way to Find the Right Defense Lawyer Fast“

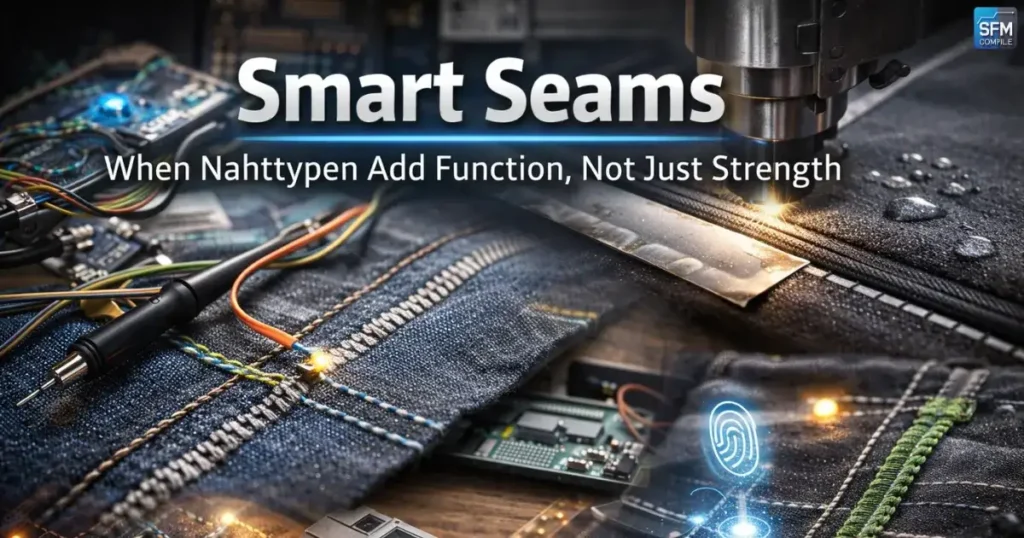

Smart seams: when Nahttypen add function, not just strength

Smart seams are seams designed to do more than hold materials together. They can route signals, create sensing zones, improve sealing, or manage thermal and moisture behavior. In technology-forward products, seams become integrated features. This requires careful choice of thread, materials, and stitch patterns so that the seam remains reliable while also supporting electronics, coatings, or barrier layers.

Conductive seam paths for wearables and textiles

Conductive thread, tapes, or printed traces can turn a seam into a connection path. This is useful for wearables, heated garments, health-monitoring textiles, and flexible sensors. The seam pattern matters because tight bends, repeated flexing, and wash cycles can break conductive paths. Nahttypen that reduce sharp folds and spread motion tend to protect functionality better, especially when paired with strain relief zones.

Sealed seams for waterproofing and hygiene

Seam sealing is crucial in rain gear, outdoor equipment, medical textiles, and cleanable surfaces. A seam can be strong but still leak if needle holes are exposed. Tapes, liquid sealants, or welded constructions block pathways for water and contaminants. These Nahttypen improve performance but add process steps and require good adhesion. The key is matching seam seal materials to the base fabric and its coatings.

Quick mid-project checklist for choosing Nahttypen

- Define the main force: tensile, shear, peel, or repeated flex

- Confirm material type: woven, knit, coated, composite, plastic, metal

- Decide if you need sealing: water, air, dust, bacteria, chemicals

- Check comfort needs: skin contact, thickness, stiffness, irritation risk

- Map production limits: machines, cycle time, skill level, automation

- Plan inspection: what defects matter and how you will detect them

- Prototype two options: one “fast,” one “overbuilt,” then test both

- Document settings: thread, needle, heat, pressure, speed, and tolerance

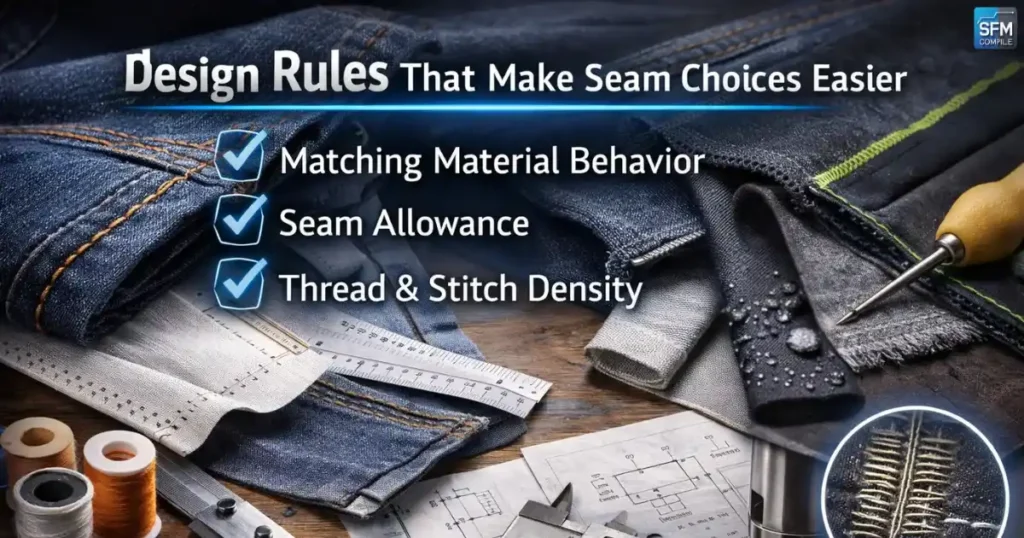

Design rules that make seam choices easier

Good seam design starts before the machine starts. The same seam type can perform differently depending on allowances, stitch density, thread choice, and how layers stack. Nahttypen should be selected with the full product in mind, including how parts are cut, handled, and assembled. A design that is “theoretically strong” can still fail if it is difficult to build consistently.

Matching material behavior: thickness, stretch, and coatings

Thicker materials often need larger needles, stronger thread, or wider seam allowances to prevent tearing. Stretch materials need seam constructions that stretch with them, or they pop under movement. Coated or laminated fabrics can delaminate if stitched badly, so bonded or welded Nahttypen may be better. Always consider how the material changes after heat, moisture, and repeated bending, not just when new.

Seam allowance, stitch density, and thread selection

Seam allowance is the “grip area” that prevents the seam from pulling out. Too small and you risk tear-out, too large and you add bulk and stiffness. Stitch density must match material strength, because too many holes can weaken fabric like a perforation line. Thread type, thickness, and finish also matter. Strong thread is useless if it cuts the fabric or degrades from UV or chemicals.

Quality control: how to verify Nahttypen in real production

Testing seams is not just for the lab. If you want consistent products, seam quality needs repeatable checks on the production floor too. Nahttypen should have measurable acceptance criteria, such as seam width, stitch balance, alignment, sealing coverage, or weld bead consistency. The best systems combine fast visual checks with periodic strength tests that confirm performance over time.

Visual inspection and measurable seam features

Visual inspection catches skipped stitches, uneven tension, puckering, misalignment, and poor edge finishing. It is even more important for welded or bonded seams, where subtle gaps can cause leaks. Measurable features like seam width, tape overlap, stitch density, and consistent spacing help reduce subjectivity. When operators know exactly what “good” looks like, defects drop and rework costs shrink.

Destructive testing and smart sampling plans

Destructive testing pulls seams to failure to reveal weak constructions or process drift. Common approaches include seam tensile tests, peel tests for bonded seams, and leak testing for sealed seams. You do not need to test every unit, but you do need a smart sampling plan. Test more during setup changes, new material lots, or machine maintenance periods, because those are the times defects spike.

Automation and machines shaping modern Nahttypen

Automation changes which seam types are practical at scale. Some Nahttypen are easy for humans but hard for robots, especially when soft materials shift. Others are perfect for machine control, like continuous welding or taped seams with guided rollers. When automation is involved, seam design must support consistent material feeding, stable alignment, and clear quality signals that sensors can detect reliably.

CNC sewing, seam tracking, and vision assistance

Modern sewing lines can use programmable patterns, guided folders, and vision systems that track seam paths. This helps repeatability, especially in products with complex curves or multiple layers. Seam tracking reduces drift, while vision-based inspection can catch skipped stitches or misplacement early. Nahttypen that keep layers stable and avoid excessive bulk are easier to automate, which often improves both speed and quality.

Robotic welding and automated bonding

Robotic welding and bonding excel at consistent pressure, speed, and heat delivery. This supports seam types that depend on precise process windows, like ultrasonic seams or heat welds. Automated bonding systems can control adhesive bead size and placement better than hand work. The tradeoff is that materials must be highly consistent, and fixtures must hold parts correctly. Seam design should include alignment features to reduce errors.

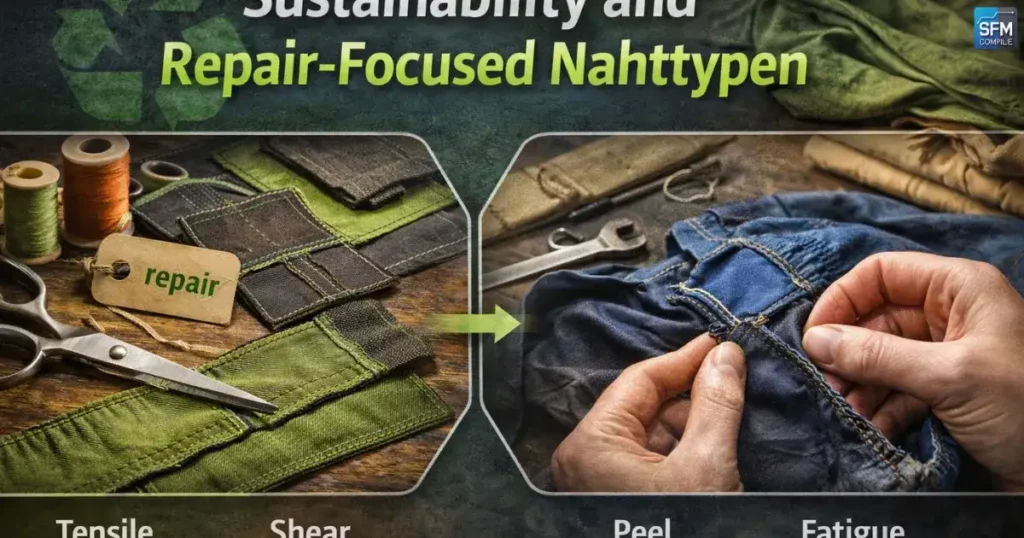

Sustainability and repair-focused Nahttypen

Sustainability is not only about materials. It is also about how long the product lasts, and how easily it can be repaired. Some Nahttypen make products stronger but impossible to disassemble. Others support easy alterations, patching, or component replacement. If you want a product to survive longer and generate less waste, seam strategy becomes a key part of the lifecycle plan.

Designing for disassembly and reuse

Repairable seams are often stitched rather than permanently bonded, especially when components may need replacement. If bonding is required, designs can include modular panels or service openings with reinforced seams. Using consistent seam types across a product can also simplify repair training and reduce mistakes. Nahttypen that avoid hidden damage, like delamination or trapped moisture, help keep reused materials reliable.

Extending product life with “service seams”

Service seams are seams placed where repairs are most likely. Examples include reinforced stress points, replaceable straps, or seam constructions that allow re-stitching without tearing the base material. Adding a little extra seam allowance in key areas can make repairs much easier later. Nahttypen that protect edges and distribute load help prevent catastrophic failures, which is better than making a seam that fails suddenly.

Key points

| Goal | Best-fit Nahttypen | Where it works well | Watch-outs |

| Maximum durability in woven fabric | Flat-felled, French seam | Jeans, workwear, bags | More steps, added bulk |

| Stretch + comfort | Overlock, coverstitch | Activewear, knits | Needs correct tension and thread |

| Waterproof or hygienic barrier | Welded seam, taped seam | Rain gear, medical covers | Material compatibility is critical |

| Smooth interior, low irritation | Bonded, enclosed seams | Wearables, base layers | Adhesive aging and wash durability |

| High-volume consistency | Welded, automated taped seams | Industrial textiles, PPE | Tight process window |

| Easy repair and long life | Stitched seams with extra allowance | Outdoor gear, upholstery | Slightly higher material use |

Conclusion

Nahttypen are a quiet technology choice that impacts strength, comfort, sealing, and product life. When you treat seams like engineered load paths, you stop guessing and start designing for real conditions. The best seam type is the one that matches the forces, the materials, and the way the product will be used, washed, flexed, and repaired.

If you are choosing between seam options, prototype at least two Nahttypen and test them under realistic stress. One should optimize speed, the other should optimize durability or sealing. That comparison reveals tradeoffs clearly and prevents costly rework later. With the right seam strategy, you get smarter products that last longer and perform better in the real world.

FAQs about Nahttypen

What does “Nahttypen” mean?

It means “types of seams,” covering different seam constructions and joining methods.

Which Nahttypen are strongest for clothing?

Flat-felled seams and enclosed seams are often strongest and resist fraying well.

Are welded seams better than stitched seams?

They can be, especially for waterproofing, but only when materials and process settings match.

Why do seams fail even with strong thread?

Because needle holes, edge fraying, poor allowances, or fatigue can weaken the material itself.

How do I pick the right seam type quickly?

Start with your main force and material, then decide if you need stretch, sealing, automation, or easy repair.

I’m Eric Nelson, a professional content writer with over 8 years of experience creating clear, engaging, and well-researched content across multiple digital spaces. I focus on turning complex topics into easy-to-understand stories that inform, entertain, and add real value for readers.

My Experience & Expertise 🚀

Multi-Niche Content Specialist:

Over the years, I’ve written across a wide range of categories including tech, crypto, business, lifestyle, fashion, grooming, celebrities, and breaking news. I specialize in content that feels current, trustworthy, and genuinely useful. 💡

Writer, Researcher & Trend Analyst ✍️

As an author at SFMCompilee.com, I cover:

Tech insights & explainers 💻

Crypto & business trends 📊

Lifestyle, fashion & grooming guides 👔

Celebrity stories & trending topics 🌟

In-depth reviews and practical guides 🧭

I write with a balance of research, experience, and reader-first thinking, making sure every piece is informative, engaging, and easy to follow without unnecessary fluff.